Welcome to our comprehensive range of high-quality machine tools. We are committed to empowering manufacturers and machining professionals with the latest innovations and top-tier solutions. Our products are sourced from globally renowned manufacturers to ensure top performance.

Our selection of machine tools is designed to deliver efficiency, and durability. In cooperation with our partners, we provide the tools you need to excel in metalworking. Each machine has different specifications depending on its application. Explore our machine tools and services and let SKM GROUP be your partner in achieving efficiency, and success in your metalworking operations.

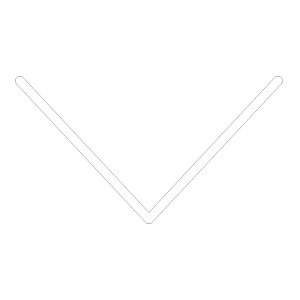

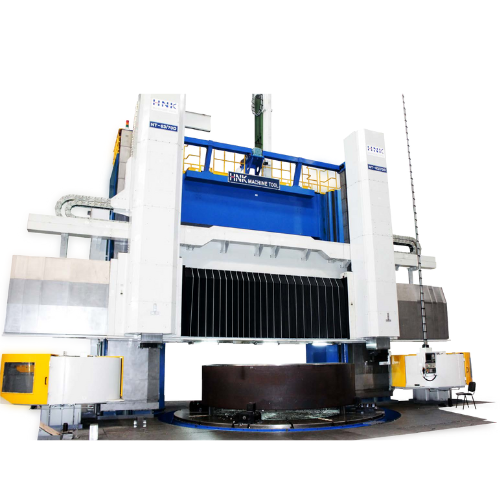

Vertical turning machine centers

Three-axis CNC vertical turning center. It guarantees high rigidity, high speed operation and high accuracy due to the improved machine features such as rigid body construction and the latest control system.

The Y-axis plays a crucial role in maximizing the capabilities of the VTC-series. Its design facilitates easy loading and unloading of jobs on the table, enhancing operational efficiency. It enables an “off-centered” cutting process, allowing for versatile machining options. Its flexible travel can be customized to meet specific customer requirements.

Two-axis CNC vertical lathe. This model guarantees high rigidity, high speed operation and high accuracy due to the improved machine features such as rigid body construction and the latest control system.

Five axes machine centers

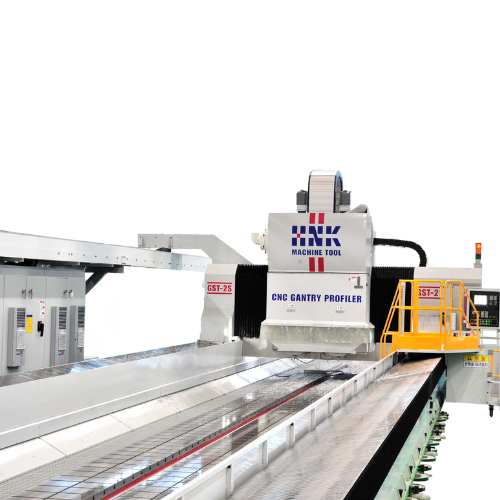

GPM-60FX is a ram-type 5-axis gantry profiler designed for machining complex shapes with versatile 5-axis surface machining capabilities.

5S-GPM is specially crafted for high-speed machining of aircraft frame parts, boasting five 12,000rpm spindles for exceptional productivity and superior surface finish.

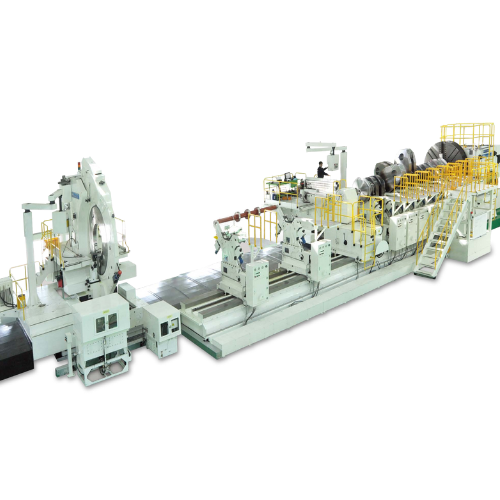

GPM-20F streamlines all cutting processes, including milling, boring, drilling, and tapping for a medium-speed crankshaft on a medium-speed vessel in a single setup.

Designed for aircraft, electronic, and automobile parts, offers high speed and precision. Featuring an optimal pallet system, it enhances work efficiency, and with an automatic universal head, it supports various surface machining jobs.

5-axis simultaneous horizontal machining center with high rigidity driven tilting head. Specialized for aerospace parts with various machining range from material such as titanium, Inconel to aluminum with high spindle speed.

HTM-30S: Rough and find cutting process on each side of a special purpose can be carried out and various cutting jobs such as milling, boring, drilling and tapping can be completed at one set-up on this model.

HTM-12: The efficiency of its multifunctional design is verified on various machining processes of crankshaft such as fine cutting of main journal, pin journal and outside of flange plus cutting inside/ outside corner R of pin journal and drilling/tapping with special attachment.

Gear cutting machines

HGG-Series is Profile Grinding Type / Thread Wheel Grinding Type of gear grinding machine. It produces various types of gears with higher speed and more precisely, and minimizes dressing time with the double dressing system. Diverse teeth are prepared by tooth-fix program and various operative convenient devices such as Automatic Balancing, AE sensor and etc. In addition, more reliable gear machining results can be achieved with tooth calibration devices.

By using an inner gear tooth cutting attachment & an outer gear tooth cutting attachment alternately on the same machine, the cutting processes of yaw & pitch bearing can be completed at one set-up. With the biggest cutting capacity, its application and with high speed steel hobber and hobbing cutter maximizes the productivity, operation and precision of huge gears for the large-sized turning tables.

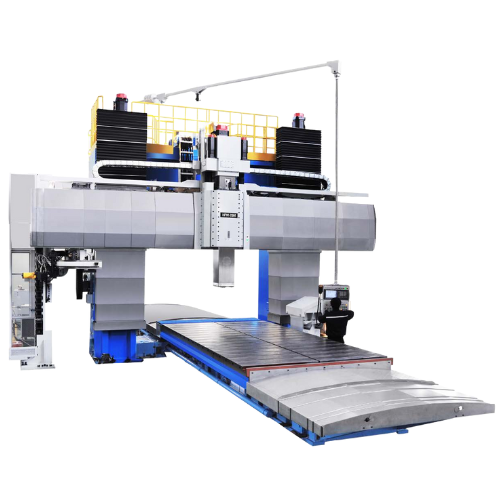

Portal type milling centers

HPM-L series: CNC large-sized double column machining center, excels in a wide range of heavy-duty machining tasks. With diverse optional attachments, it accommodates various applications in a single setup, making it particularly suitable for cutting large components in ship engines, power generators, and steel mill facilities.

HPM-H series: Derived from its robust cutting structure, the HPM-H series is the latest CNC machine tool model with a high-speed spindle and feed rate. Ideal for a broad range of applications in industries like automobile, plastics, and press parts.

HPM-M series: Double column machining center, is designed for precise and heavy-duty machining across various workpieces. Its rigid body construction ensures exceptional machine longevity and productivity.

GPM-60FX is a ram-type 5-axis gantry profiler designed for machining complex shapes with versatile 5-axis surface machining capabilities.

5S-GPM is specially crafted for high-speed machining of aircraft frame parts, boasting five 12,000rpm spindles for exceptional productivity and superior surface finish.

GPM-20F streamlines all cutting processes, including milling, boring, drilling, and tapping for a medium-speed crankshaft on a medium-speed vessel in a single setup.

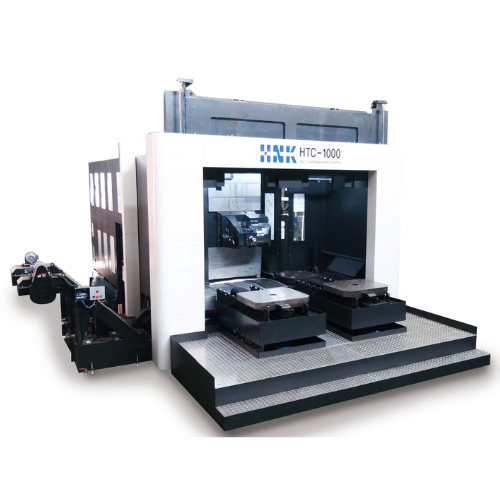

Boring and milling machine centers

Powerful, high precision HFB-Series floor type CNC horizontal boring machine is designed for heavy duty machining of large workpieces. Its stabilized ram extension design provides superior accuracy by preventing thermal elongation and by compensating the ram bending force.

The HB Series CNC horizontal boring & milling machine provides superior rigidity for your heavy-duty machining needs.

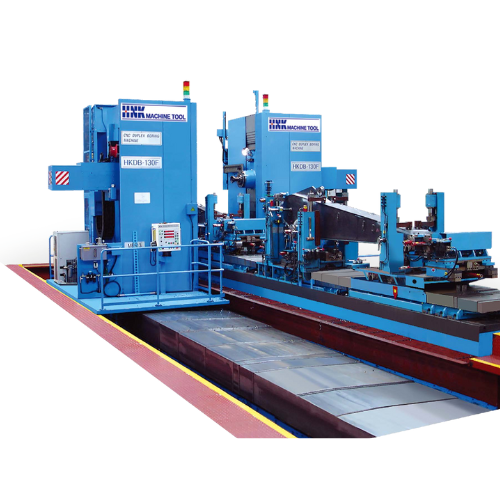

The HKDB models are of the moving type CNC boring with two spindle heads. They are designed to machine both sides of workpieces simultaneously providing remarkable reduction of cycle time and precision symmetrical machining. Their automatic pallet changer eliminates machine idle time providing unparalleled productivity.

The HKDB-F models, which are column-moving duplex boring machines, have two columns traveling along a fixed table. Two columns can travel along a fixed table simultaneously or independently. The time for set-up can be minimized by extending the X-axis stroke(a fixed table), and their precise and rapid machining capability makes it possible to do the most difficult machining jobs with efficiency.

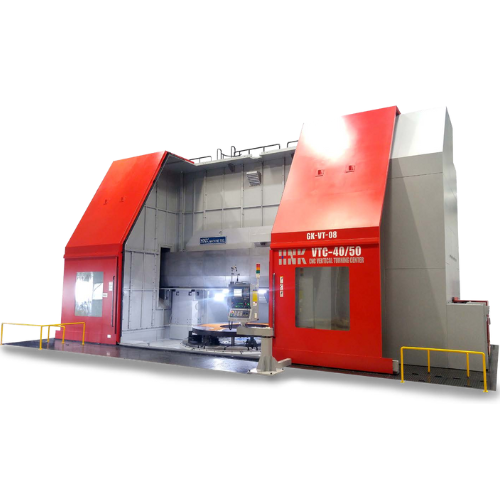

Horizontal turning machine centers

HL-series is suitable for diverse types of workpieces such as wind mill shafts, large-sized ship engine crankshafts, propeller shafts, and rudder stock in various industries. This model has excellent machining capability covering precise and complicated to heavy cutting processes.

Generalized model with two slide ways structure with high precision and rigidity for flexible machining range. Improving convenience of operation adding manual operation function.

Crankshaft lathe with one carriage and crankpin turning device with hydrostatic bearing. Machining of journals and crankpins of semi-built crank-shafts for marine diesel engines.

Special purpose machine tools

Designed for numerous applications: aircraft parts, electronic parts, machining aerospace engine parts, highly alloy steel such as inconel, titanium, machining of aircraft frame parts, machining the finger slots of turbine engine blades, automobile parts.

Company

SKM DOO BEOGRAD

VAT: 113094779

Connect

- Email: v.sergeev@skm.rs

- Phone number: +38162 975 6796

- Bulevar Milutina Milankovica 120B, Belgrade

ALL RIGHTS RESERVERD | SKM GROUP